Off-Grid Solar Inspection: An 8-Point Checklist to Keep Your System Safe and Reliable

Solar systems are built to last, but they aren’t “set it and forget it.” Time, weather, vibration, thermal expansion, and well-intentioned DIY changes can introduce problems that quietly impact performance or, worse, create safety risks.

Regular solar system inspections help catch small issues before they develop into equipment damage, downtime, or fire hazards. Whether you’re fully off-grid or running a hybrid system, this checklist will help you maintain a safe and reliable system.

Why regular solar inspections matter

Most system failures don’t happen suddenly. They develop over time. A solar inspection is preventative maintenance. It’s like going to the dentist every six months to nip cavities in the bud and avoid a root canal.

Common issues we see during inspections include:

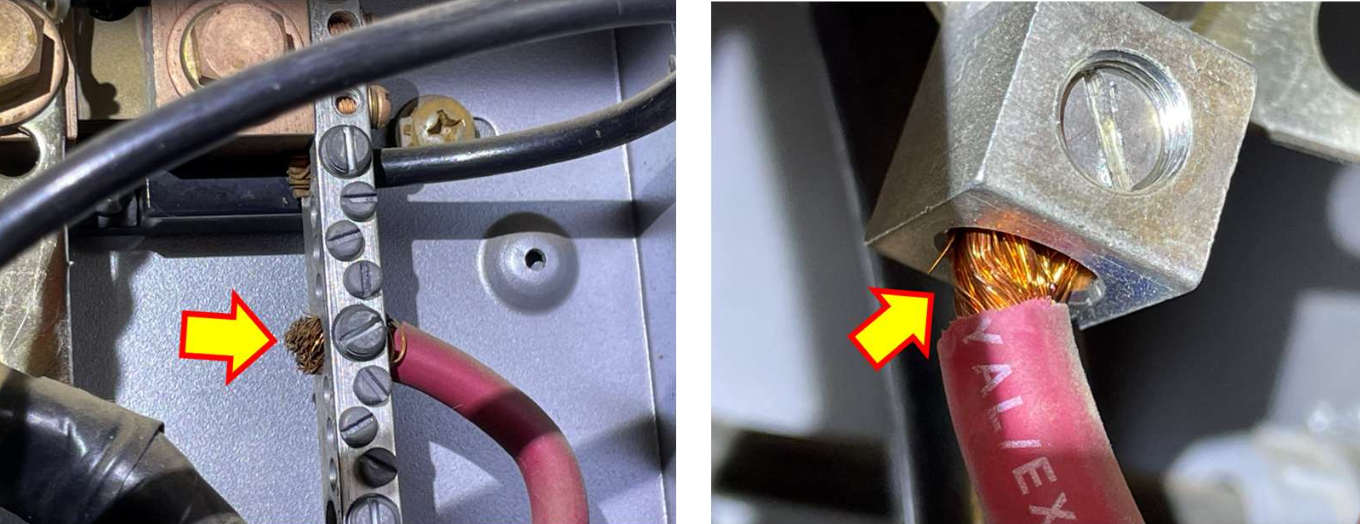

Loose electrical connections that create excess heat.

Undersized or mismatched circuit protection.

Inverter fan wears due to a dusty environment.

Battery connections that were never properly torqued.

Wiring damage from rodents or UV exposure.

Moisture intrusion in outdoor enclosures.

Exposed wiring without ferrules are a safety hazard.

Left unchecked, these problems can reduce energy production, shorten equipment lifespan, and increase safety risks. Regular inspections protect your investment and help ensure your system performs as expected.

The 8-point solar system inspection checklist

Use this checklist as a starting point for routine visual inspections. Always follow proper safety procedures and shut down equipment when required.

1. Solar panel condition

Inspect panels for cracks (front and back), delamination, discoloration, or dirt buildup. Even minor damage can reduce output or worsen over time.

2. Mounting hardware

Verify that all mounts, rails, and fasteners are secure. Wind, snow load, and thermal expansion can loosen hardware over time, creating stress on panels and wiring.

3. Wiring and conduit integrity

Look for frayed insulation, cracked conduit, corrosion, or signs of rodent damage. Wiring issues are one of the most common causes of system faults and safety problems.

4. Connector and terminal tightness

MC4 connectors, terminal lugs, and bus bars should be fully seated and secure. Loose connections increase resistance, leading to heat buildup, failure, and fire.

We ensure all battery connections are properly torqued.

5. Inverter condition and ventilation

Check for fault codes, unusual noises, or overheating. Vents and cooling fans should be clean and unobstructed, as poor airflow shortens inverter life. Change filter periodically if present.

6. Battery health and connections

Battery cables should be properly sized, strain-relieved, and torqued per specifications. If you use lead-acid batteries, inspect them for electrolyte level, corrosion, swelling, or leaks.

Poorly maintained lead-acid batteries leak toxic chemicals.

7. String balance and electrical consistency

For systems with multiple strings, verify that current is reasonably balanced. Uneven strings can indicate wiring issues, shading problems, or failing components.

8. Overcurrent protection and grounding

Confirm that fuses and breakers are correctly rated and installed where required. Proper grounding and bonding are essential for both safety and code compliance. “Exercise” the circuit breakers every few months to ensure proper functioning.

How often should you inspect your solar system?

Don’t skimp on solar system inspection, especially if you live in harsh environments (e.g., high wind, high UV, and extreme temperature fluctuations).

Mark your calendar to perform quarterly visual inspections on your panels, mounting mechanism, inverter, and batteries. Schedule annual detailed inspections to catch electrical and performance issues. Also, perform quick checks after major weather events.

DIY checks vs. Professional inspections

Homeowners should regularly perform basic inspections, such as visual checks. However, tasks like electrical measurements, torque verification, string balancing, and grounding validation require the right tools and expertise.

A professional inspection goes beyond fixing immediate issues. It also includes preventive measures (e.g., tightening connections and applying thread-locking compounds) — like a dentist scraping off plaque to help prevent cavities. An experienced professional also verifies that your system is operating safely and efficiently to maximize your investment.

Keep your solar system at tip-top shape

Solar systems fail quietly before they fail completely. Regular inspections help prevent lost production, expensive repairs, and avoidable safety hazards.

We provide off-grid solar inspections to help ensure your system operates safely and efficiently. Schedule an inspection to protect your investment and peace of mind.