Common Off-Grid Solar Safety Mistakes

As an off-grid solar system ages, components deteriorate. Also, many people have ad hoc maintenance and repair work done over time. Unfortunately, we have seen quite a few initial installations and subsequent repair work that don’t meet safety standards.

While getting an inspector’s stamp of approval may not be everybody’s cup of tea, nobody wants a fire hazard in their backyard. Let’s review common safety issues that could be lurking in your solar system.

Off-Grid solar safety checklist

Here are the items we check during a safety evaluation:

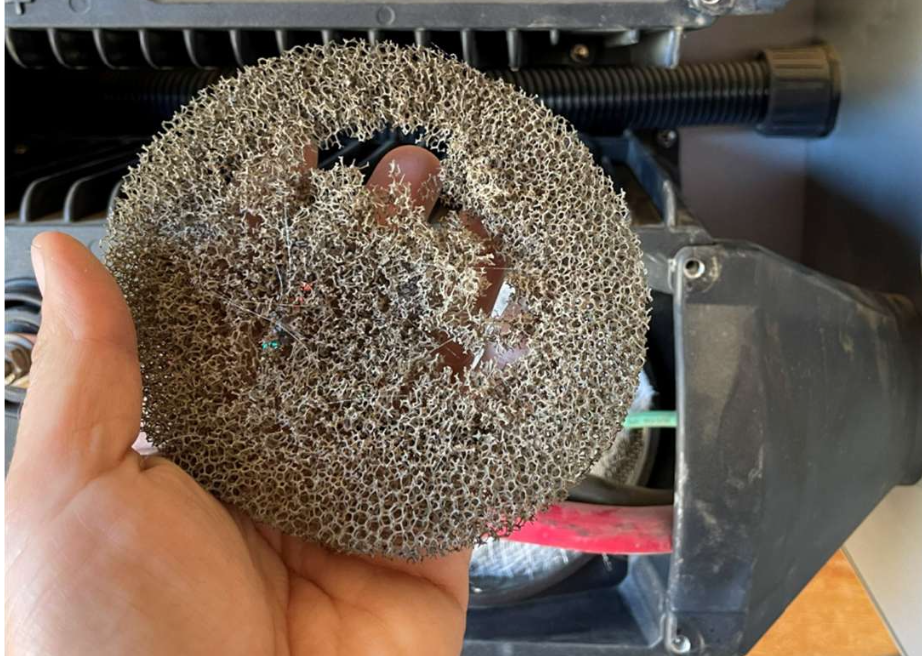

☑️ Clean and functioning inverter fans

Inverters generate significant heat and rely on active airflow to keep internal components within safe operating temperatures. When fans become clogged with dust or filters are neglected, airflow drops dramatically, causing the inverter to run hot, throttle output, or shut down unexpectedly.

A disintegrating inverter filter.

☑️ Battery connections

Bolts not torqued to manufacturer specifications can loosen over time from vibration, thermal expansion, and the natural cycling of battery charge and discharge. Even a slightly loose battery lug creates high resistance, leading to heat buildup, melted terminals, voltage drop, and, in worst cases, thermal runaway or fire. A threadlocking compound should be applied to all battery nuts to keep connections tight.

A safety check to ensure all battery connections are torqued to specs.

☑️ No signs of battery leakage

Lead oxide (a toxic and corrosive substance) leaking from lead-acid battery vents, seams, or around the terminals indicates overcharging, overheating, or cracked cases that allow electrolyte vapor to escape and deposit solids. It’s a clear warning of internal failure or improper charging.

Lead oxide oozing out of batteries is bad news.

☑️ Balanced current distribution

Current imbalances between paralleled off-grid solar strings under the same light-load conditions signal underlying issues that can compromise system performance and safety. When strings don’t share current evenly, the higher-producing ones work harder and run hotter, accelerating module degradation and increasing thermal stress on wiring and connectors. Meanwhile, the lower-producing string(s) risk hotspot formation or bypass diode damage.

☑️ Secure connections

Loose or poorly seated conductors create high-resistance points, which can generate heat, cause arcing, and lead to intermittent or catastrophic failures, especially in high-amperage DC circuits. A simple tug test can capture many common installation errors.

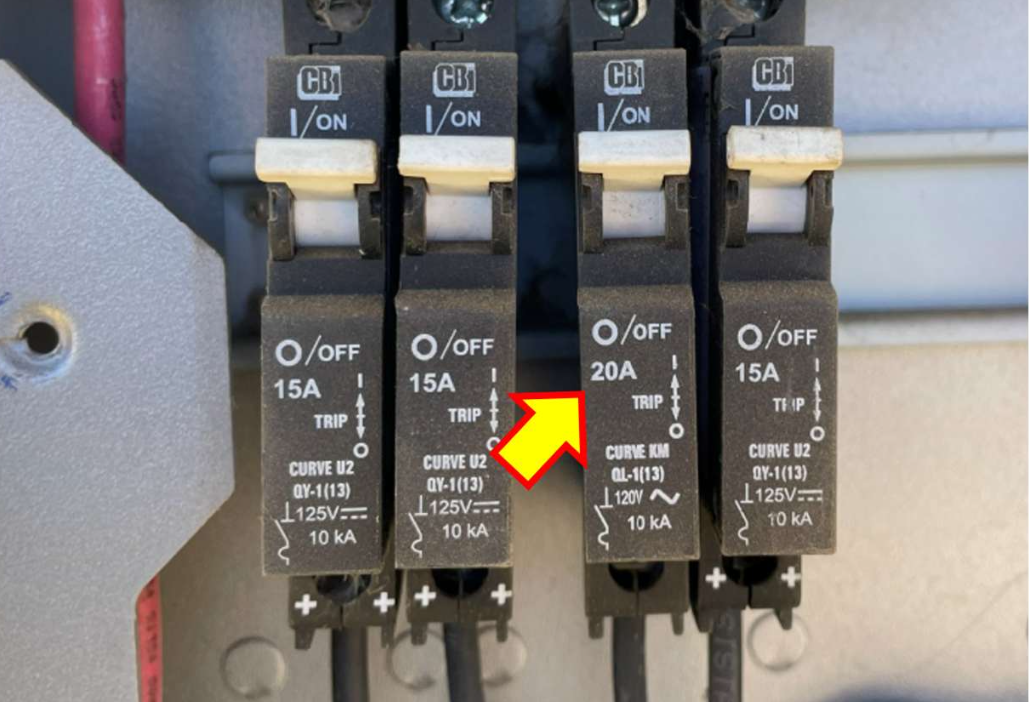

☑️ Matching circuit breakers

Parallel circuits using breakers of different ratings (e.g., 15A, 15A, 20A, 15A) can lead to dangerous fault conditions. The string protected by the higher-rated breaker(s) can continue feeding current into a fault or backfeeding into other strings long after the lower-rated ones have opened. This mistake defeats the purpose of having coordinated overcurrent protection and increases the risk of conductor overheating, insulation failure, and even fire.

An example of mismatched circuit breakers.

☑️ Rodent resistance

Rodents are attracted to the warmth of inverters, charge controllers, and battery enclosures. They may chew through unprotected PV wiring, conduit, or insulation — leading to shorts, ground faults, and complete system failure.

☑️ Moisture management

Poorly sealed junction boxes, conduit runs without drain paths, or battery enclosures that trap condensation allow water to accumulate, accelerating corrosion, causing intermittent faults, or creating shock hazards.

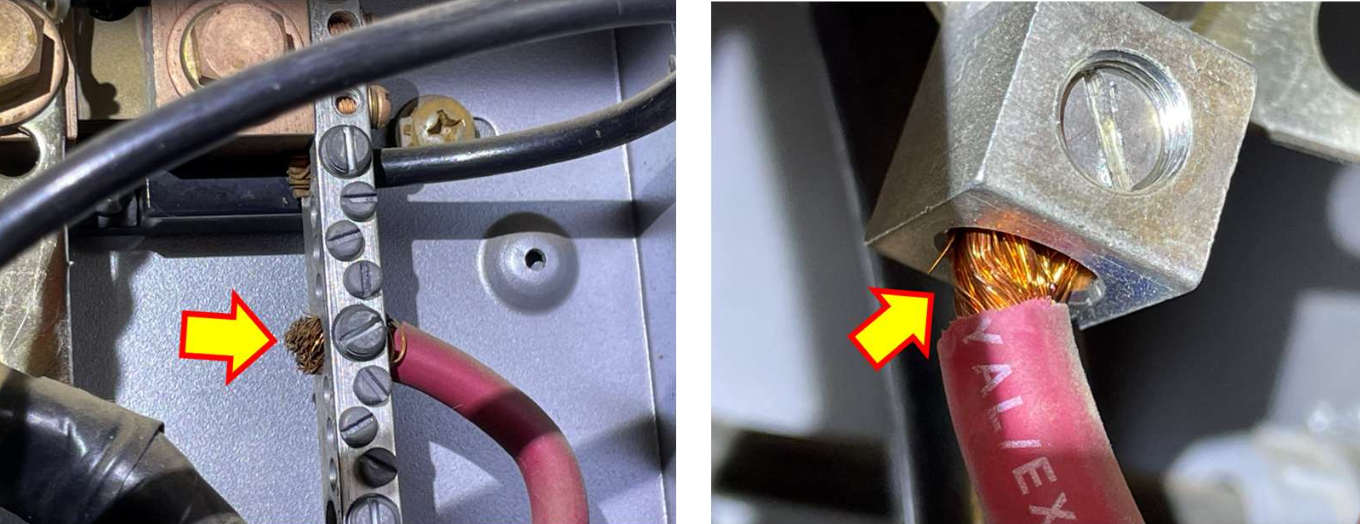

☑️ Ferrules for stranded wire

Using ferrules on stranded wire is required by code. A properly crimped ferrule consolidates the strands into a solid, uniform termination that maintains full contact surface area and stable resistance under vibration and thermal expansion. This critical practice reduces the risk of melted terminals, nuisance faults, and component damage.

Missing ferrules is a code violation.

☑️ Oxidation prevention

Noalox or other oxidation-inhibiting compound should be applied to prevent corrosion on copper, aluminum, or steel components (e.g., lugs, terminals, busbars, and module connectors) — especially when different metals are in contact. Oxidation increases electrical resistance at the connection point, causing voltage drop, heat buildup, and in severe cases, arcing or complete connection failure.

☑️ Grounding and strain relief

Proper grounding is required by code. It reduces the risk of shock hazards, equipment damage, or fires. Meanwhile, strain relief prevents mechanical stress on electrical connections that may cause wires to gradually pull out of terminals due to vibration, thermal expansion, wind movement, and more — leading to loose connections, arcing, or intermittent faults.

☑️ Fuses of the correct rating

A fuse rated too high won’t blow when a fault occurs, allowing excessive current to flow long enough to overheat wires, damage equipment, or start a fire. Conversely, one that’s rated too low can cause nuisance blow during normal operation, interrupting power and masking real issues, such as an improperly sized or configured circuit.

☑️ Wires of appropriate gauge

Undersized conductors can overheat under normal operating currents, especially in high-amperage DC circuits where voltage drop and heat buildup occur more quickly than in AC wiring. Excessive heat shortens the lifespan of insulation and may cause melted jackets, arc faults, or even fire.

☑️ Proper wiring practices

Poor wiring practices include using aluminum wire on copper contacts without any oxidation-inhibiting compound or putting copper wiring on aluminum busbars. Meanwhile, wires with unclear and ambiguous color coding (e.g., a tape of one color wrapped around a wire of another) can lead to confusion and accidents.

Protect your investment with a safety evaluation

Proper maintenance goes a long way in ensuring safe and continuous operations of your off-grid solar system. Our solar system health check gives you insights to make targeted improvements, helping your investment last longer. Get in touch to schedule a consultation.